At Reguentex we carry out everything in-house and are able to conveniently provide clients with everything that they need to develop, produce and source a high-quality end product. From finding the right material, designing patterns and selecting prints/embroideries, through to cutting and packing, we manage everything for you.

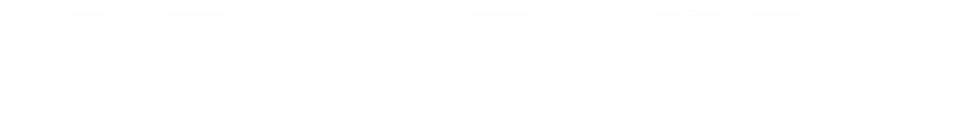

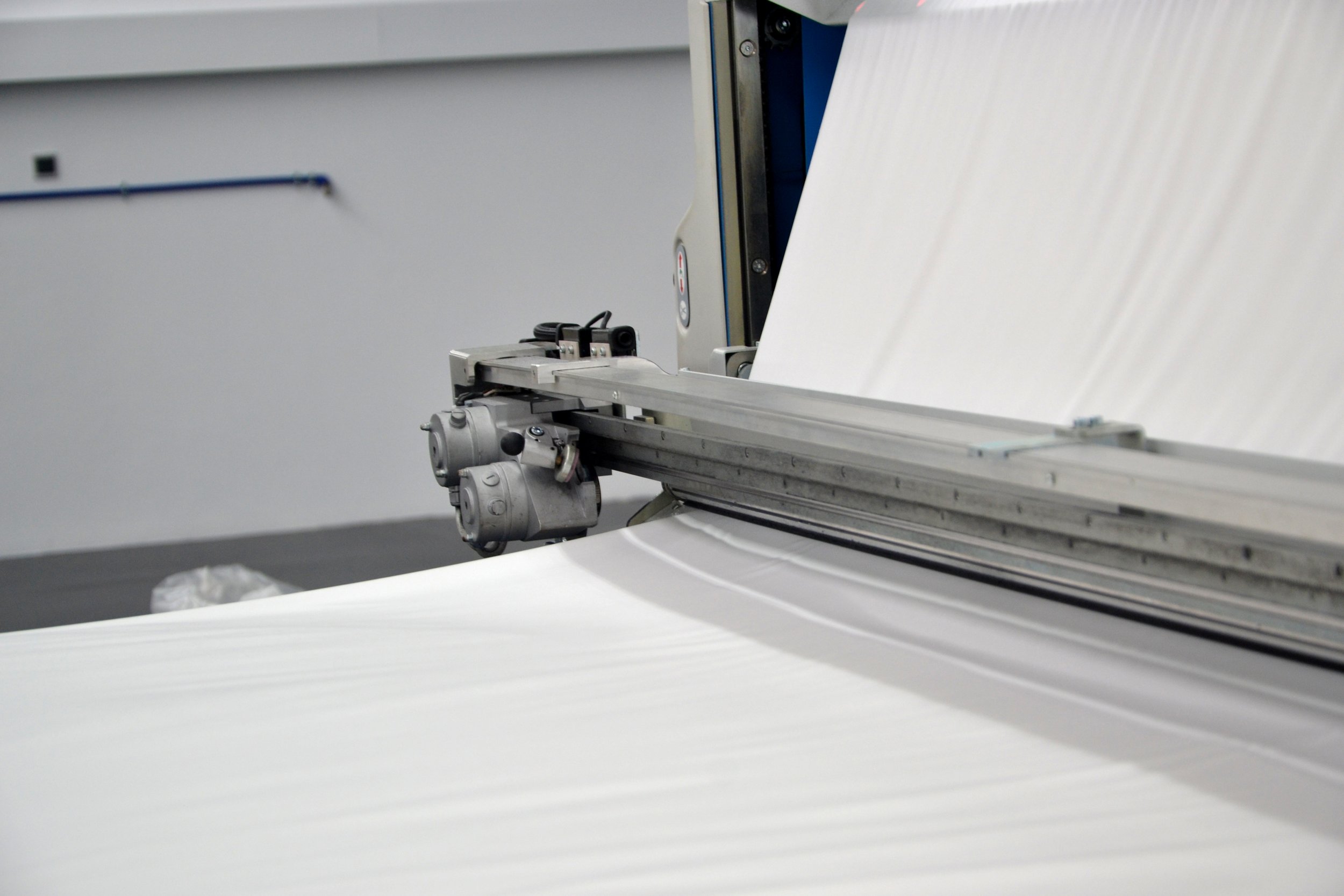

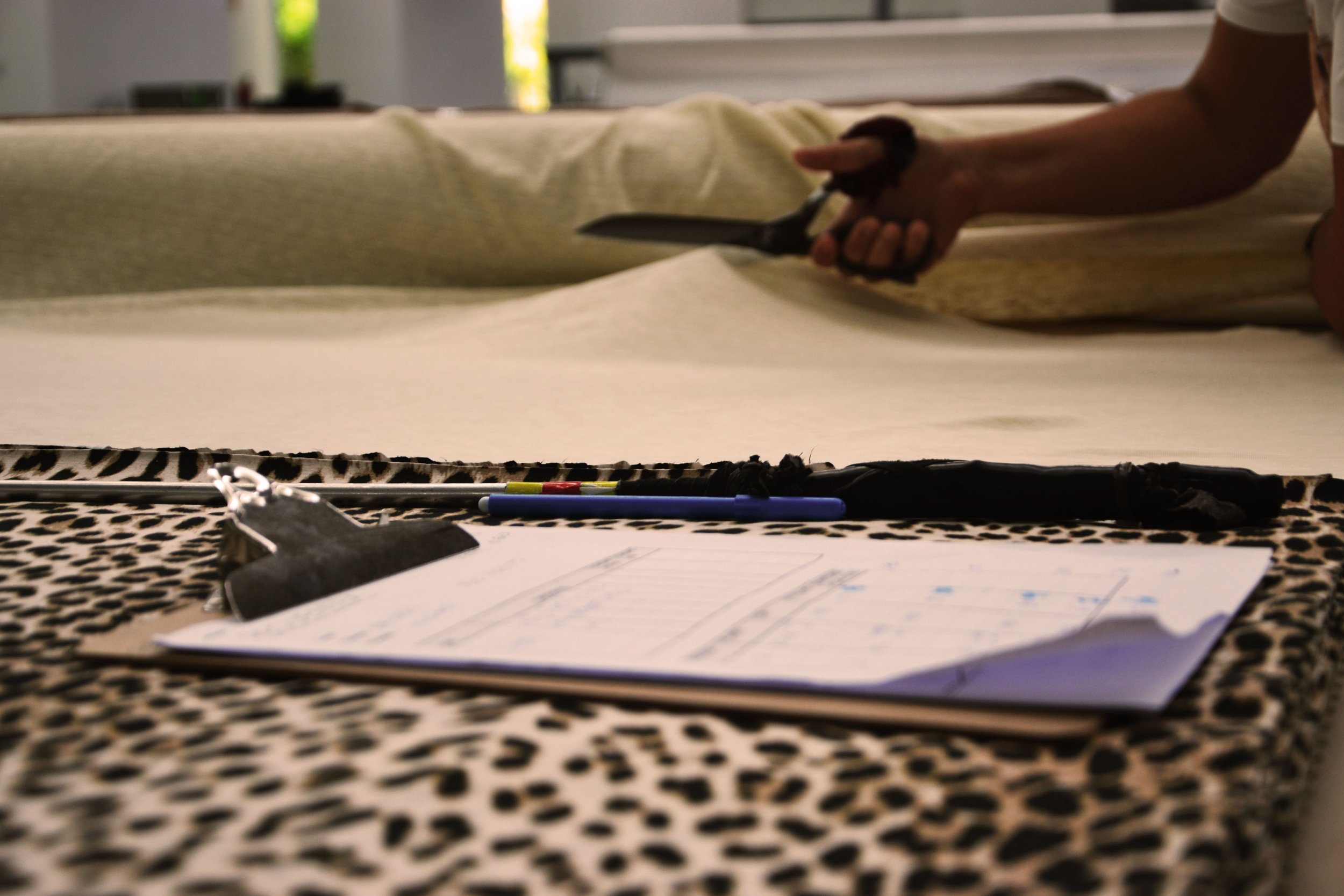

PATTERN MAKING &CUTTING AREA

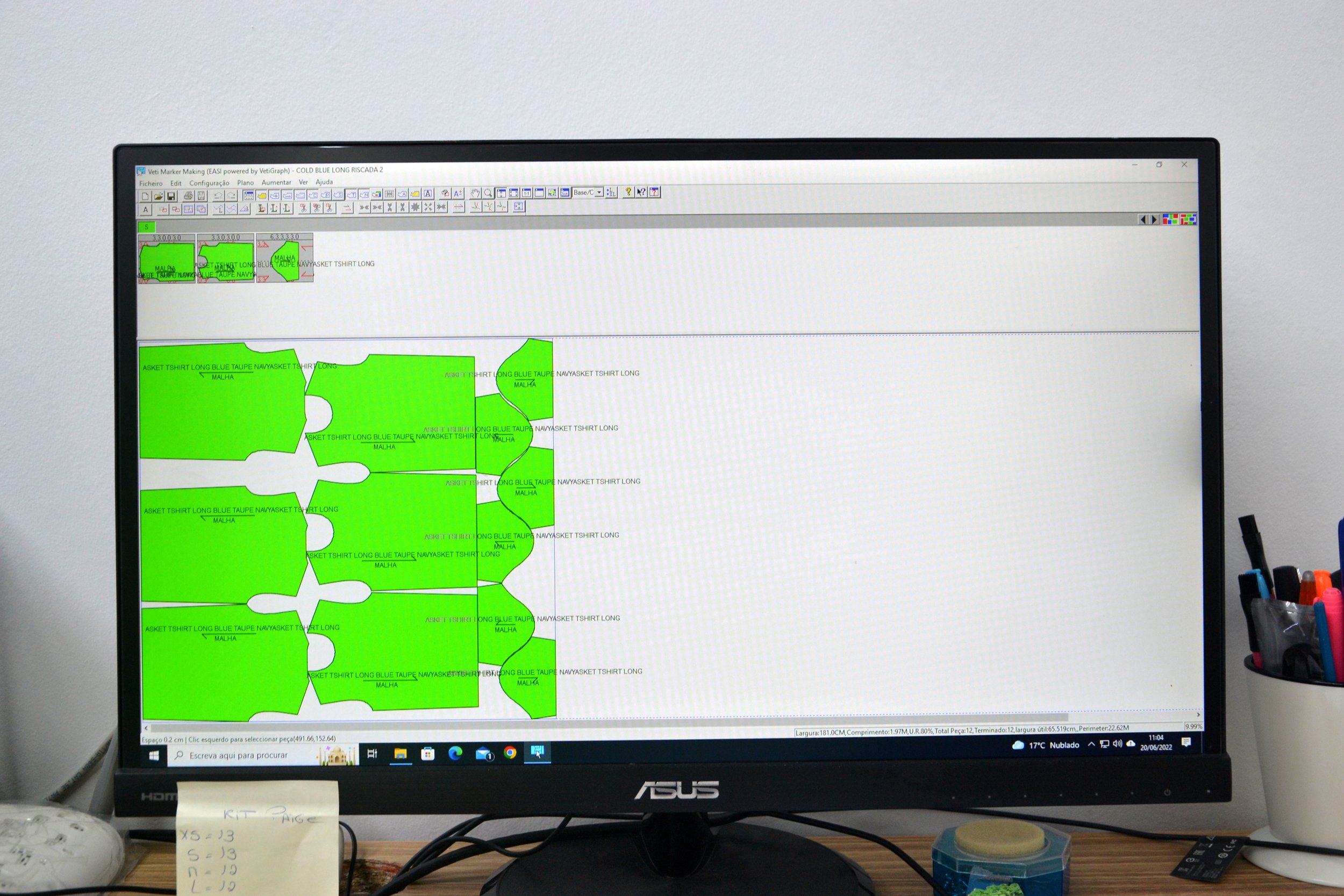

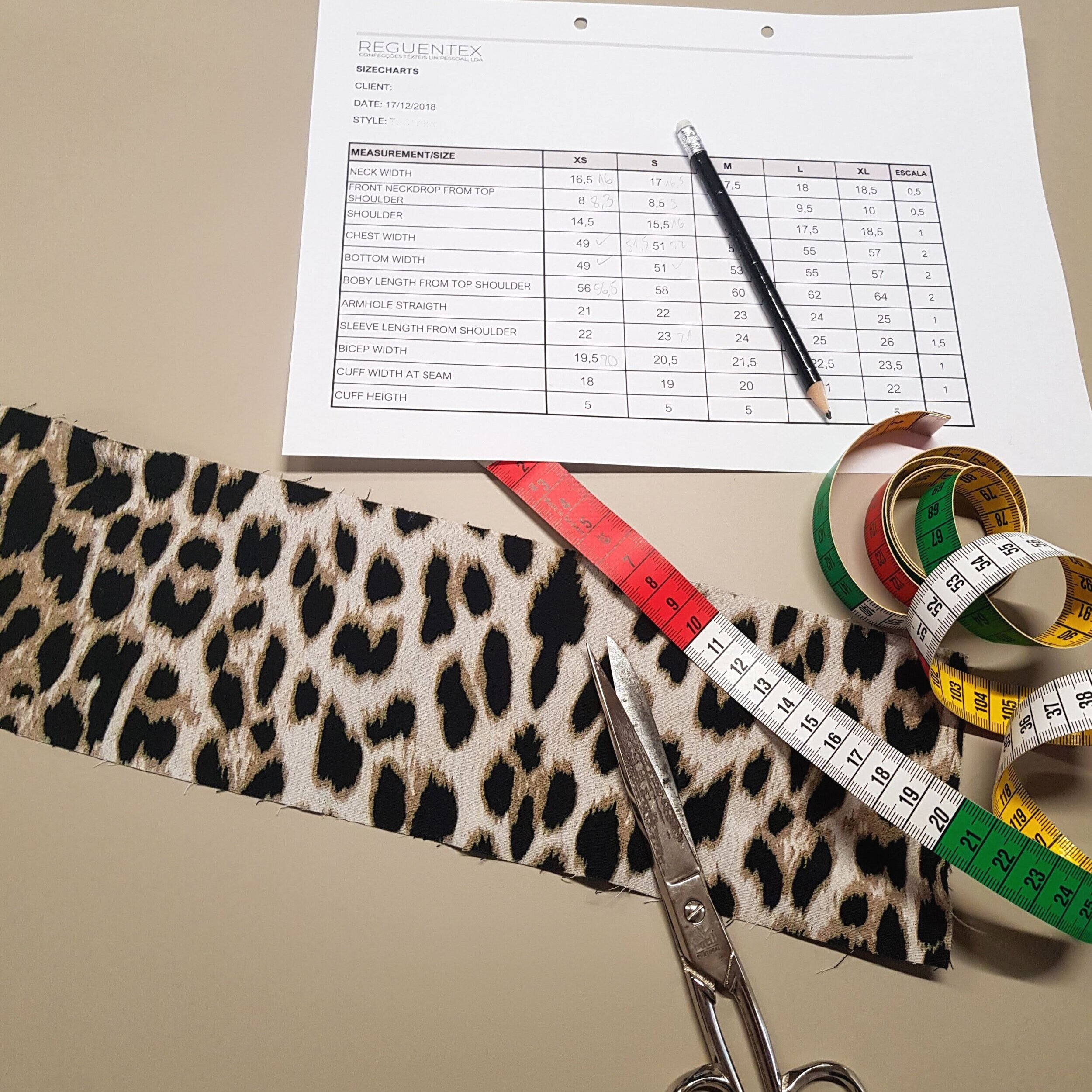

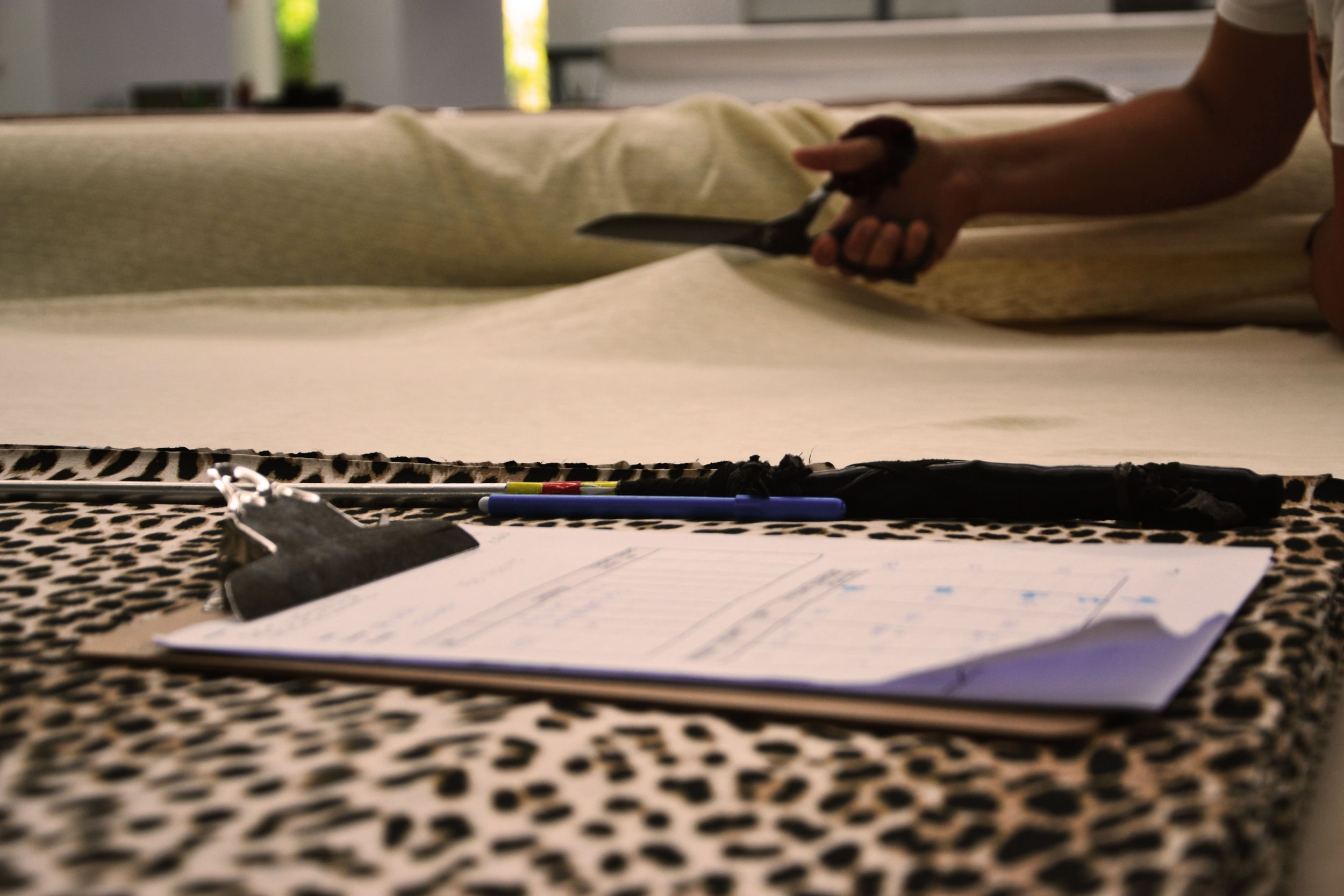

Our equipment allows for both manual working and the use of CAD-assisted design. This allows us to find an approach that works for you as we can easily adapt our processes based on the materials you want to use and the end product you want to produce.

Our investment in pattern placing software has helped to significantly optimise our manufacturing process and keep the waste of raw materials to an absolute minimum.

PRODUCTION LINE

At Reguentex we currently have two production lines that allow us to simultaneously produce both larger scale and smaller, more intricate orders.

Both our lines are able to produce a wide variety of high-quality products from different materials, including pieces that are traditionally more difficult to manufacture.

PACKING AND QUALITY CONTROL AREA

We understand quality control is critical to an end product. Throughout the production process, we undertake both internal and external checks at every stage, from development right through to the shipping of the final order.

We offer a number of different packing and shipping options that we can tailor to your needs. Reguentex is also proud to offer alternatives to plastic packaging as part of our drive to keep waste to a minimum.